By Drake A. Wauters, AIA | May 2016 Technique

When reading about fearless world famous architects and the building scientists that support their projects with their active skins, advanced materials, and many innovations one would think that change comes swiftly to the design of buildings. However for most buildings this is certainly not true and to that point I would like to say a few important things about the humble basement.

Buildings with basements which number in the many tens of millions in the US if we consider housing are infamous for experiencing moisture problems in most regions. The University of Minnesota Extension page “Moisture in basements: Causes and Solutions” does a good job of describing the typical moisture challenges for most basements including where hydrostatic pressure is not present.

The moisture most of us first think of is liquid water that leaks through walls and up through joints in slabs. Avoiding problems on paper with liquid water has been generally addressed by the building codes and our customs of building for some time. Remediation when leaks do occur can range from subdrains and sump pumps, to new waterproof barriers, to bentonite augmentation of the surrounding soil, and to the provision of new positive drainage and barrier measures at grade. So liquid water can usually be understood and addressed even if repairs are costly. Liquid water in our living space is immediately noticeable and commands our full attention right away.

On the contrary, what does not get much attention is vapor drive through our foundation walls (Figure 1) and in some cases slabs in to our occupied spaces and how damaging it is to our health and our buildings and contents. And how that uncontrolled vapor drive expands our carbon footprint and wastes our money. Vapor is the gaseous form of water present all around us. When the relative humidity in the atmosphere or in materials is moderate or on the low side we pay little attention to vapor drive but for millions of buildings from homes, to commercial, to institutional uses, vapor drive can be an almost year round problem due to local weather conditions but critically it can also be a year round problem as moist soils and materials adjacent to our building foundation walls and slabs can lead to near continuous vapor drive in to our buildings.

Figure 1: Photo by Drake A. Wauters, AIA

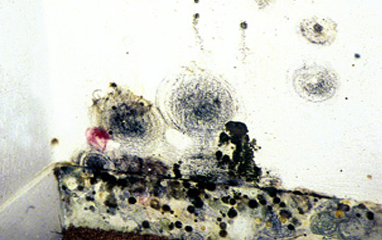

The presence in our buildings of unwanted vapor levels often leads to mold, mildew, and odor (Figures 2 and 3) even without condensing to liquid water. Once vapor drive elevates relative humidity to dew point levels, liquid water can form leading to accelerated mold and bacterial mold growth, building and finish damage, furniture and contents damage, drastically reduced indoor air quality, and enriched conditions supporting many types of insect infestations that carry their own indoor air quality hazards such as increase allergy and asthma levels. What is also true is that most buildings have indoor air handlers that recirculate much of or all the interior air meaning that high humidity and poor air quality in basements quickly impact the rest of the building and more importantly the occupants.

Figure 2: EPA

Figure 3: EPA

Since vapor drive is not liquid water which is considered an emergency when present, the building codes have not been forceful in mandating the control of this problem. Leaving most projects to be designed and delivered without addressing the problem since addressing it would in most cases be considered a code plus expense which few owners care to shoulder as a first cost no matter how small. As a result the operator of the building and the occupants pay the price for this missed opportunity.

The price can be physical cost such as adding reverse side vapor barriers which are fairly new and not useful on materials other than concrete or fully grouted masonry, replacing interior finishes and construction more frequently, not using certain spaces for occupants or valued items like records or computers, using HEPA and activated charcoal filters, increasing fresh air ventilation, adding dehumidification systems, or running air conditioning for longer cycles and using air reheaters to keep the supply air at comfortable temperatures. All of these are costly and imperfect means to an end but they all have an energy price tag and carbon footprint.

Material costs for a widely available vapor impermeable Class I cold liquid applied waterproofing providing a perm of 0.02 and primer is around $1.10 per SF of wall area while a widely available Class II dampproofing providing a perm of 0.75 is around $0.20 per SF. A $0.90 per SF delta in material costs over a typical 1,400 SF house basement wall area works out to a $1,260 material savings but at what cost down the road? Though both perm numbers may not seem high, a 0.75 is over 35 times higher than a 0.02! This is one example where saving pennies per square foot on first costs could lead to spending thousands throughout the life of the building to deal with high levels of vapor permeance. For reference, there are three vapor permeability classes for vapor retarders listed in Chapter 2 of the 2015 International Residential Code: Class I at ≤ 0.1 perm, Class II at 0.1 to 1.0 perm, and Class III at 1.0 perm to 10 perms. Of these only Class I is considered a vapor barrier. Higher than 10 perms is not considered a vapor retarder at all.

To be fair, vapor barriers have been required under basement slabs for a long time. However these have often not been high performing products and are frequently damaged during concrete placement. For this reason the building code still prohibits untreated wood use in direct contact with slabs on grade even indoors. The relative humidity of concrete is naturally high as moisture is retained perpetually in the material after curing. This means it takes very little moisture or vapor drive from the substrate to tip the relative humidity of the concrete upward leading quickly to interior problems.

Even when a basement may be designed to resist hydrostatic pressure and successfully stops liquid water intrusion, the vapor drive is rarely addressed directly. The worst offender is often basement walls since in many buildings the dampproofing or waterproofing used on them is not a vapor barrier and in some cases has little vapor retarding ability at all. What is more, many basements still in use have been built with no water barrier on the exterior. On top of this, site conditions change after the construction of buildings with the most common change the settling of soils around the basement leading to surface water drainage toward the building and low spots allowing higher levels of surface water to saturate the soils for longer periods of time.

Basement walls are in many ways directly exposed to the effects of rain fall and rain saturated soils. Further magnifying this problem, many buildings in place have no subsurface drainage that would remove this water such as foundation drains and even when provided initially may have failed due to crushed or blocked pipes, blocked filter courses or fabrics, blocked outlets, or long term displacement leading to new low points that let water remain in the cavities indefinitely. The writer has in fact come across projects with no outlets to foundation drains where infiltration to the soil was the only means of discharging liquid water from the soil under the assumption that one side of the building had dry soils when one side had saturated soils.

The good news is that unlike many challenges we as architects face this century, the design solution to stopping excess vapor drive in to basements is simple. If designing a basement specify and detail a waterproofing for the basement walls that is a Class I vapor barrier as defined in ASTM E96, meaning it has a vapor permeance level of 0.1 perm or lower. And when specifying and detailing the basement slab use a Class I product that is also well detailed to address penetrations and transitions and tough enough to withstand the physical challenges of construction. This is in addition to what measures addressing water intrusion are already required in the code.

Choices of waterproofing vary but a few examples include active systems that may rely on bentonite clay or crystalline waterproofing that expand or fill minute voids and cracks to block the capillary action of liquid water to passive systems that form a waterproof coating that could include liquid applied membranes (Figure 4), self-adhering peel and stick membranes, to membranes set in the forms for concrete resulting in a bond to the face of the concrete. In the case of active waterproofing an additional membrane can be included to act as a vapor barrier since most active systems do not act as vapor barriers on their own. Dampproofing such as a thin coating of an asphaltic material are not considered waterproofing or vapor barriers, however in most localities dampproofing is used on basement walls where the water table is not high enough to lead to liquid water intrusion.

Figure 4: (WBDG). Protection board is not specifically required for either product compared in this article.

As discussed, commonly used measures such as dampproofing do not address vapor drive from humid soils through the walls to the interior space. However, some forms of insulation being used more frequently such as closed cell foam can act as vapor barriers so their use can be part of the overall vapor management solution. While spray applied closed or open cell foams are becoming more common so are measures to insulate entire slabs on grade using closed cell foam board substrates. Whichever solution is pursued the designer should take precautions to prevent trapping moisture by inadvertently providing multiple vapor barriers that could allow humidity levels to collect within the construction as this could lead to significant deterioration.

The hard part to the fix is changing codes and building customs so a more helpful approach to preventing vapor intrusion can become the new normal. Since basements are expected to be damp in our popular culture as they were a direct offshoot of root cellars, coal bins, and crawl spaces, many people still accept that they are substandard spaces that require little attention when designed and built. While ironically they consume a large share of our resources every year after that in many cases as we struggle to deal with the inevitable moisture and health problems we could have avoided.

Measures to reduce energy use in buildings cut off some customs that were the norm in basements such as increasing outdoor air ventilation to manage odors or humidity and using dehumidification most or all of the year. One example of an energy intensive fix that is not sustainable is using a dehumidifier as a permanent solution to excess vapor drive inward. The typical dehumidifier one would buy at the hardware store uses around 300 watts of energy an hour so running this all day is around 7.2 kWh a day. The US Energy Information Administration reports the average American home uses 911 kWh per month so running that small humidifier would add 219 kWh per month, or an increase of a whopping 24 percent.

We expect to do more with our buildings and live in healthier conditions than in years past but to do this we need to move beyond stalled assumptions that have not been serving us well. We need to see that some changes are an easy ‘A’.

Additional Reading

The Whole Building Design Guide (WBDG) maintains the Building Envelope Design Guide (BEDG) at https://www.wbdg.org/design/envelope.php. Start on their page on below grade systems https://www.wbdg.org/design/env_bg_overview.php.

The Pacific Northwest National Laboratory (PNNL) maintains a searchable database of Building Science Publications at http://bse.pnnl.gov/. Start on their page on Foundations & Floors – Basements: https://basc.pnnl.gov/building-components/browse/180314below.

The Building Science Corporation (BSC) maintains a valuable building science site. Start on their page BSD-103: Understanding Basements http://buildingscience.com/documents/digests/bsd-103-under.